- 美国GSG美标管螺纹量规

- 美国GSG石油螺纹规│GSG牙形板

- 美国GSG美标ASME螺纹规

- 美国GSG精密量规│进口量仪

- 美国GSG螺纹指示规│螺纹量仪

- 美国GSG倒角量规│锪孔量规

- 瑞士Trimos测高仪│Trimos测长机

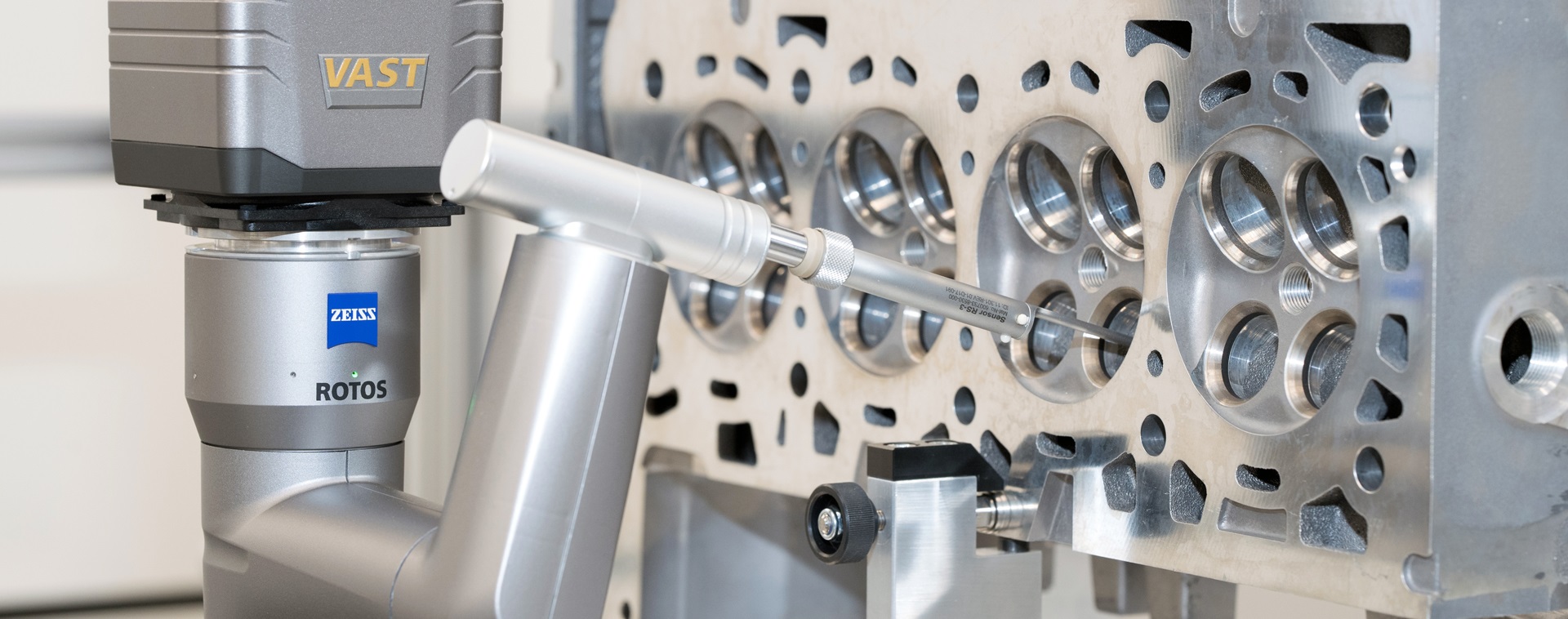

- Hexagon影像仪│海克斯康三坐标

- 苏州Mitutoyo日本三丰量具

- Fischer菲希尔涂层测厚仪

- Elcometer易高涂层测厚仪

- GE超声波探伤仪

- 奥林巴斯超声波探伤仪

- GBIS超声波探头

- Bruker布鲁克光谱仪

- 赛普斯SCIAPS光谱仪

- Western Instrument仪器

- G.A.L. Gage焊接量规

- Clark硬度计│Sun-Tec

- 日本future-tech硬度计

- King便携式布氏硬度计

- Rex Gauge邵氏硬度计

- Ames便携式洛氏硬度计

- Hemco Gage螺纹规

- PMC Lone Star石油量规

- Vermont螺纹规│VTG螺纹规

- GageAssembly螺纹规

- Threadmaster进口螺纹规

- WESTport Corporation

- Threadcheck螺纹规│三线规

- Mueller Gage沟槽量仪

- Kroeplin精密卡规

- 美国环球Universal Punch

- 德国Schwenk进口内径量仪

- Allen Gauge and Tool

- Fowler High Precision

- Swiss Precision Instruments

- Flexbar Machine Corporation

- Acem螺纹规│Stub Acme螺纹规

- 苏州工量具│测量仪器

- Wrentham Tool Group

- Meyer Gage针规、梅尔量规

- ASKER橡胶硬度计

- NAKANISHI高速主轴

- OJIYAS螺纹规│OJIYAS气动量仪

- Microset 复制胶

- DeFelsko涂层测厚仪

- OSG丝锥│OSG螺纹规

- Western Gage 气动量仪检具

- Michigan Spline Gage Co

- Southwest Calibration Service

- McCord and Company

- Pennoyer-Dodge Company

- Pi Tape Texas, LLC

- BARCOR INC.

- Advanced Systems and Designs

- Calmetrics Inc

BSPT是英制圆锥管螺纹标准:螺纹的牙型角为55°、螺纹具有1:16的锥度;

属于惠氏螺纹家族,多用于欧洲及英联邦国家,常用于水及煤气管行业;

国标查阅GB/T7306-2000。

BS-21 System A vs. System B Taper Pipe Thread Gauges

Most simply stated, the difference between

the System-A and the System-B BS-21 British Standard Taper Pipe Thread Gages is

the way the gauges are read/used.

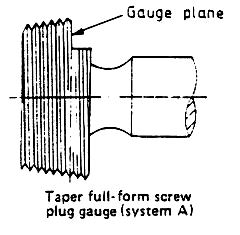

System-A Screw Thread Gages

The System-A British Standard Taper Pipe Screw Thread Gauges have a single

gauge plane which is used as the measurement reference point. Appropriate use

of System-A gages includes taking a measurement from the gage plane to the edge

of the part thread. That data is then compared to the data in BS-21 to

determine if the part thread is within tolerance. Depending on the thread size

and if it is the internal or external product screw thread; the leading edge of

the BS-21 tapered product screw thread must fall within plus or minus 1.0 to

1.5 turns from the notch or surface of the British Standard Taper Pipe Screw

Thread Gage. If you notice that this method of reading the gauge is similar to

the NPT series of gages which is read/used with plus or minus 1 turn from the

notch or edge of the NPT gauge. Because of that, the British Standard System A

is a favored by the USA gage makers who use the gage exactly as they would a

NPT gage by counting +/- 1 turn for all sizes. This method is good because it

does not require any training of the user of the gauge, and the resulting

product thread is closer to product thread nominal size; but it also reduces

the manufacturing tolerance for the product thread and thus increases the

production costs. System-A design has been abandoned in the ISO 7/2 gages.

For the System-A British Standard

Taper Pipe Screw Plug Gage the gauge plane is a notch at the large end of

the British Standard Taper Pipe Screw Plug Gage. The British Standard Taper

Pipe Screw Plug Gauge is applied to the product screw thread and is gauged

based on the measured value from the end of the product screw thread to the

gauge plane on the British Standard Taper Pipe Screw Plug Gage. To correctly

use/read the British Standard Taper Pipe Screw Plug Gauge compare the resultant

measurement with the information given in BS-21. If counting turns is your desired

method of testing the part; for consistency I suggest that you keep with the

NPT norm of +/- 1 turn from end of the product screw thread to the gauge plane.

Be advised that BS-21 the number of turns varies depending on the thread size

from the from +/-1.2 turns to +/-1.5 turns from the end of the product screw

thread to the gauge plane.

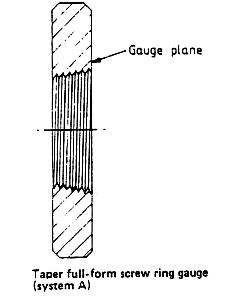

For the System-A British Standard

Taper Pipe Screw Ring Gage the gauge plane is the surface which is

presented to the product screw thread; not the surface used to take the part

size measurement. The pitch diameter at the ring gage gauge plane is identical

to the pitch diameter of the plug gage gauge plane. The British Standard Taper

Pipe Screw Ring Gauge is applied to the product screw thread and is gauged

based on the measured value from the end of the product screw thread to the

British Standard Taper Pipe Screw Ring Gage surface nearest the end of the

product screw thread. To correctly use/read the British Standard Taper Pipe

Screw Ring Gauge compare the resultant measurement with the information given

in BS-21. If counting turns is your desired method of testing the part; for

consistency I suggest that you keep with the NPT norm of +/- 1 turn from end of

the product screw thread to the gauge plane. Be advised that BS-21 the number

of turns varies depending on the thread size from the from +/-1 turn to +/-1.5

turns from the end of the product screw thread to the gauge plane.

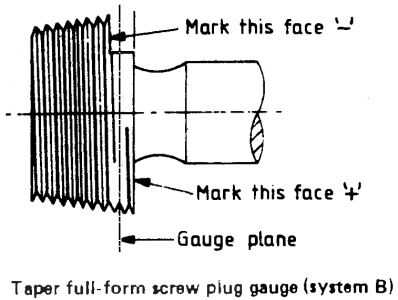

System-B Screw Thread Gages

The System-B British Standard Taper Pipe Screw Thread Gauges have the tolerance

limits ground into the System-B British Standard Taper Pipe Screw Thread Gages

as a step. This allows for easy determination of the standard allowed pipe

screw thread tolerance limits. One end of the System-B British Standard Taper

Pipe Screw Thread Gauge is the maximum taper screw thread size and the step is

the minimum taper screw thread size. The System-B British Standard Taper Pipe

Screw Thread Gages have the steps marked with a plus (+) and a minus (-) to

indicate the maximum and minimum product taper screw thread positions. The

System-B British Standard Taper Pipe Screw Thread Gauge is applied to the

product taper screw thread which is gauged based on how the end of the product

taper screw thread presents itself to the System-B British Standard Taper Pipe

Screw Thread Gage. The end of the product taper screw thread must fall between

the end of the System-B British Standard Taper Pipe Screw Thread Gauge and the

gage step. This system is considered the standard by the UK gauge makers, and

is preferred elsewhere in the world. When we sell NPT taper screw thread gages

to European customers they prefer the two-step design as described above. The

2-step System-B gage paradigm is what has been adopted for the ISO 7/2 pipe

screw thread gages.

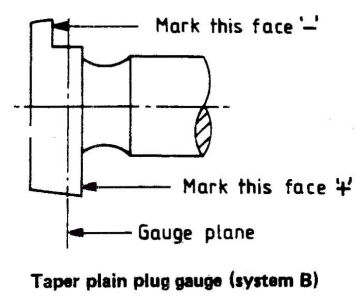

System-B Plain Taper Gages

The BS-21 British Standard System-B also has defined System-B British Standard

Plain Taper Pipe Gauges. The System-B British Standard Plain Taper Pipe Gages

are used to check the taper of the screw thread at the crest of the product screw

thread. One end of the System-B British Standard Plain Taper Pipe Gauge is the

maximum product screw thread size and the gauge step is the minimum product

screw thread size. The System-B British Standard Plain Taper Pipe Gages have

the steps marked with a plus (+) and a minus(-) to indicate the maximum and

minimum product screw thread positions. The System-B British Standard Plain

Taper Pipe Gauge is applied to the product screw thread and the product is

gauged based on how the end of the product screw thread presents itself to the

System-B British Standard Plain Taper Pipe Gage. The end of the product screw

thread must fall between the end of the System-B British Standard Plain Taper

Pipe Gauge and the gage step. The System-B British Standard Plain Taper Pipe

Gauges are to be used in addition to the System-B British Standard Taper Screw

Thread Pipe Gages; not in place of them. The System-B Plain Taper

Plug Gage is not carried over to ISO 7/2; however; the System-B Plain Taper

Ring Gage is found in the gages designed for ISO 7/2. The term:System-B is not

found in ISO 7/2.

BS-21 vs.

ISO-7

The product screw thread of the ISO-7 is technically equivalent to the product

screw thread of BS-21. The ISO-7 screw thread gages are different than the

BS-21 screw thread gauges because of differences in the gage design paradigms

used by different standards bodies. Because of these two facts, two conclusions

can be made. First; BS-21 screw thread gauges may be used to measure ISO-7

screw threaded product, and ISO-7 screw thread gages can be used to measure

BS-21 screw threaded products. Second; in a gauge dispute all parties should

harmonize the screw thread gages to the same standard. The use of screw thread

gauges all made to the same standard may not resolve the dispute, but it should

make the resolution easier.